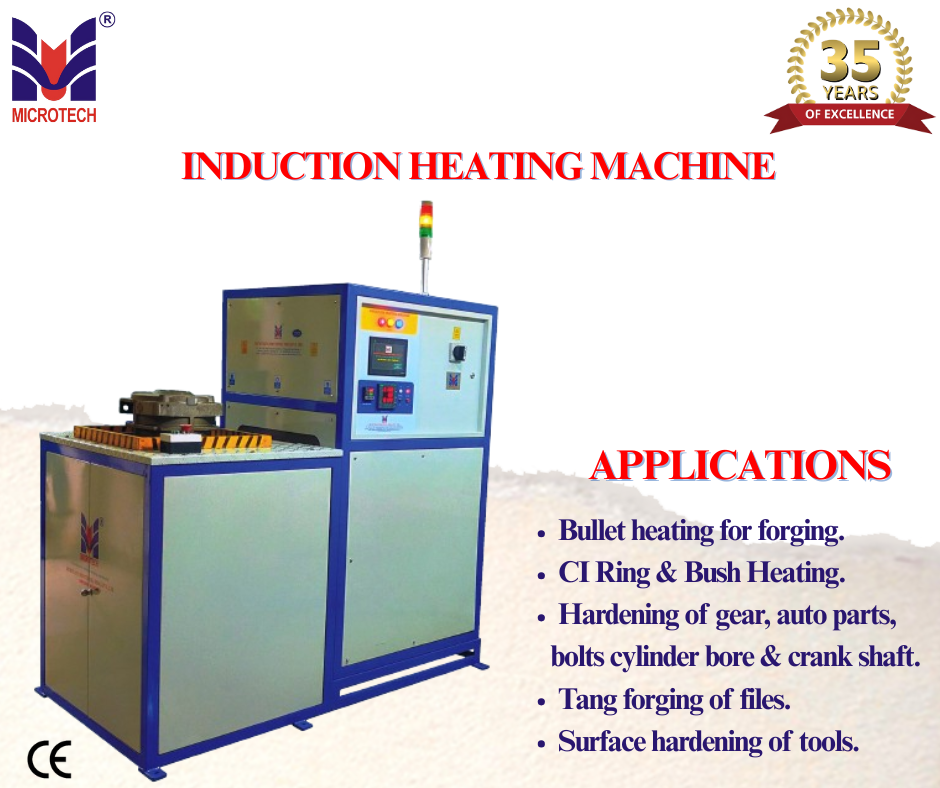

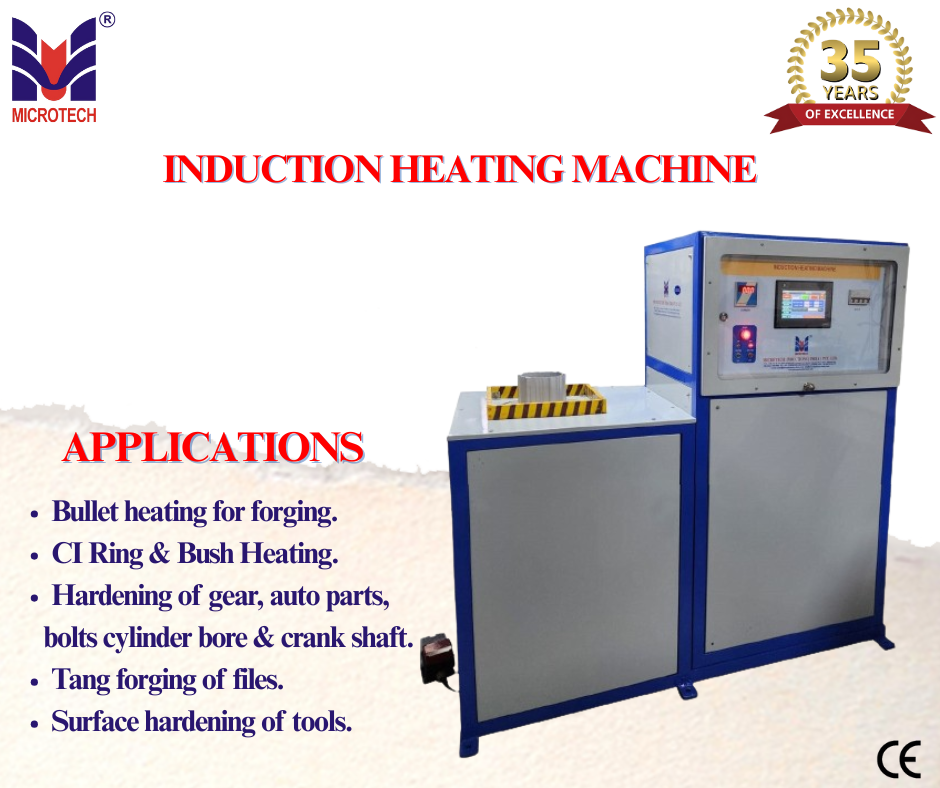

Induction Forging Machines

98900.0 INR

Product Details:

- Voltage 415 Volt (v)

- Usage Industrial

- Type Induction Forging Machines

- Size Standard

- Material Mild Steel

- Application Forging

- Product Type Induction Forging Machines

- Click to view more

X

Induction Forging Machines Price And Quantity

- 1 Unit

- 98900.0 INR

Induction Forging Machines Product Specifications

- Forging

- Induction Forging Machines

- 415 Volt (v)

- Standard

- Mild Steel

- Induction Forging Machines

- Industrial

Induction Forging Machines Trade Information

- 50 Unit Per Month

- 30 Days

- Wooden boxes & customized packing also available.

- All India

- ISO 9001:2000 Certified

Product Description

In track with the market development, we are manufacturing, exporting and supplying a supreme quality assortment of Induction Forging Machines. Offered machine is designed and manufactured by our adroit professionals using world class components and cutting-edge technology as per the set industry norms. Further, these machines are rigorously tested by our experts on various quality parameters. Our Induction Forging Machines are widely used in forging industry for different applications.

Features ofÃInduction Forging MachinesÃ

- Quick heating

- Excellent durability

- Long service life

Efficient Heating Technology for Forging

Our Induction Forging Machines utilize advanced induction technology to achieve fast, uniform heating of steel and mild steel, making them essential for industrial forging applications. Their high energy efficiency results in reduced operational costs and consistent output quality.

Reliable Choice for Industrial Applications

Designed for demanding environments, these machines are built with premium components to ensure long-term reliability and minimal maintenance. Their adaptability makes them suitable for a wide range of forging tasks across different sectors.

Sourced from a Trusted Indian Supplier

As a leading exporter and manufacturer based in India, we adhere to rigorous quality standards. Our machines are available in standard sizes and can be integrated into existing industrial setups for immediate operation.

FAQ's of Induction Forging Machines:

Q: How does an Induction Forging Machine operate in an industrial setting?

A: Induction Forging Machines work by using electromagnetic induction to rapidly heat steel or mild steel components to their forging temperature. This process is fast, precise, and energy efficient, making it suitable for large-scale industrial applications.Q: What materials can be processed with your Induction Forging Machines?

A: Our machines are engineered to handle a variety of metals, with a specific focus on mild steel and steel. These materials respond efficiently to induction heating, resulting in effective forging performance.Q: When should I consider using induction forging instead of traditional forging methods?

A: Induction forging is ideal when your production process requires precise control over temperature, faster heating cycles, improved energy efficiency, and consistent quality. It is especially beneficial in high-throughput industrial settings.Q: Where are your Induction Forging Machines typically used?

A: Our machines are widely installed in industrial plants and forging units across India. As an exporter, we also supply to international clients in the automotive, aerospace, and general manufacturing industries.Q: What is the typical process flow when using an Induction Forging Machine?

A: The process starts by placing a steel or mild steel workpiece within the induction coil. The machine is energized, rapidly heating the workpiece to forging temperature, after which it is immediately transferred to the forging press or hammer for shaping.Q: How can your Induction Forging Machines benefit my business?

A: These machines enhance productivity by delivering quick and uniform heating, reduce energy consumption, and improve the safety of the forging environment. Their consistent performance helps maintain high quality standards in forged products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Induction Heating Machine ' category

|

MICROTECH INDUCTIONS (INDIA) PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese