Induction Vacuum Melting Furnace

140000.0 INR/Unit

Product Details:

- Condition New

- Usage Melting Furnace

- Size Standard

- Product Type Vacuum Induction Melting Furnace

- Voltage 220-440 Volt (v)

- Warranty 1 Year

- Click to view more

X

Induction Vacuum Melting Furnace Price And Quantity

- 140000.0 INR/Unit

- 1 Unit

Induction Vacuum Melting Furnace Product Specifications

- Melting Furnace

- 1 Year

- 220-440 Volt (v)

- Standard

- Vacuum Induction Melting Furnace

- New

Induction Vacuum Melting Furnace Trade Information

- 50 Unit Per Month

- 30 Days

- Wooden boxes & customized packing also available.

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO 9001:2000 Certified

Product Description

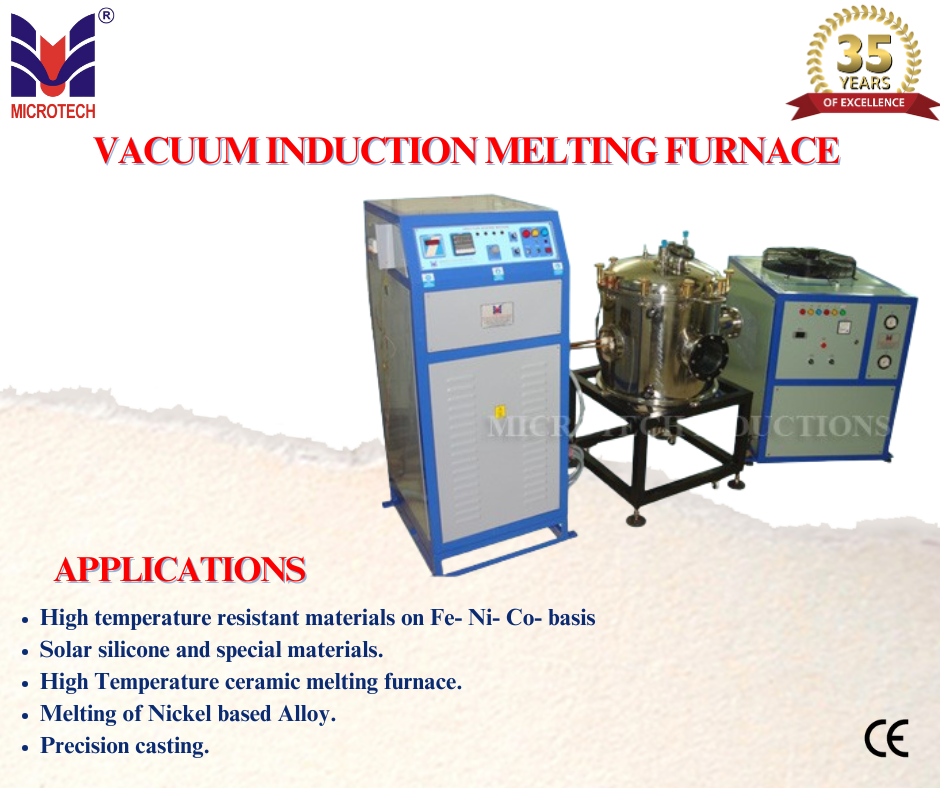

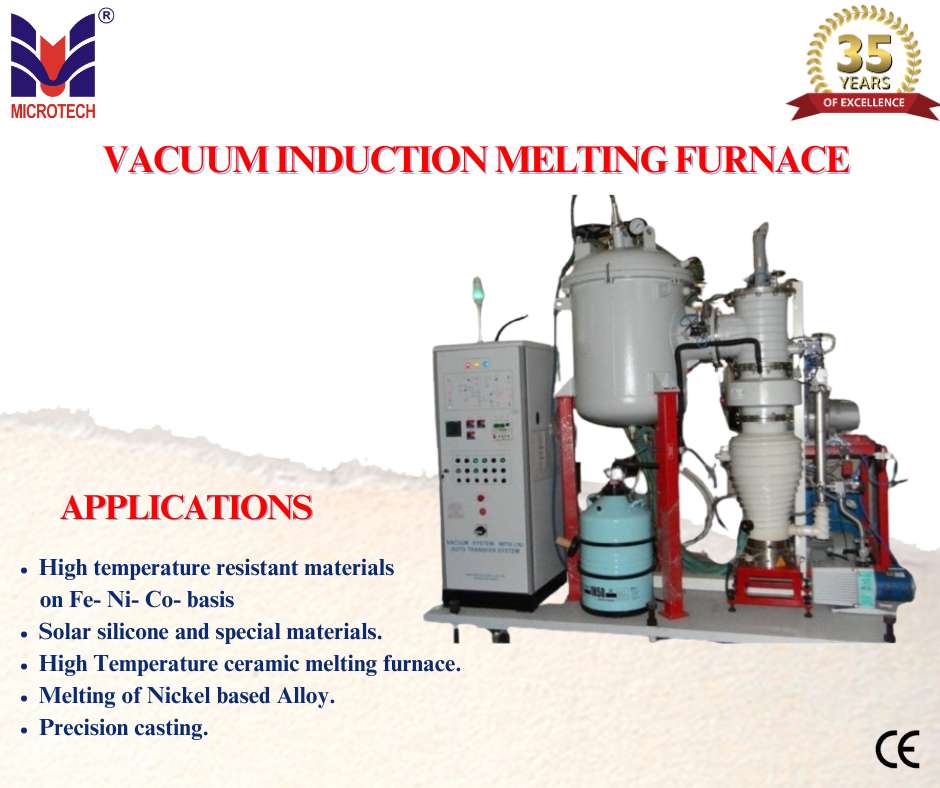

Induction Vacuum Melting Furnace

We export and supply a wide assortment of Induction Vacuum Melting Furnace that is manufactured using qualitative raw material and advance technology. Specially designed for various melting applications, these melting furnaces are known for their reliable performance and require less maintenance. Further, our offered Induction Vacuum Melting Furnace is highly praised by the clients for their availability in various specifications and at economical price range.

Features of Induction Vacuum Melting Furnace

- Innovative design

- Optimal productivity

- Top quality and long life

High-Efficiency Industrial Melting

Our Induction Vacuum Melting Furnace combines advanced induction heating with a vacuum environment, ensuring clean and precise melting for metals. Ideal for manufacturing units, research labs, and metal processing plants, this furnace supports high productivity and optimal material properties.

Flexible Voltage, Reliable Performance

Designed to operate at 220-440 Volt, the furnace accommodates diverse industrial power setups. The robust build and standardized size make it easy to integrate into existing workflows, providing consistent performance and minimal downtime.

Quality Assurance and Support

Each unit is backed by a 1-year warranty, reflecting our commitment as an exporter, manufacturer, and supplier from India. Customers benefit from dependable support, timely service, and expert guidance throughout the product lifecycle.

FAQ's of Induction Vacuum Melting Furnace:

Q: How does the Induction Vacuum Melting Furnace ensure precise melting results?

A: By utilizing induction heating within a controlled vacuum environment, the furnace minimizes oxidation and contamination, resulting in high-purity and homogeneous metal melts ideal for sophisticated industrial applications.Q: What materials can be melted using this furnace?

A: This furnace is suitable for melting a variety of metals, including steel, titanium, precious metals, and special alloys, making it versatile for numerous industrial uses.Q: When should I use an induction vacuum melting furnace over conventional melting methods?

A: The furnace is recommended when you require maximum purity, enhanced alloy consistency, or process sensitive metals that are prone to oxidation or contamination with conventional methods.Q: Where is the Induction Vacuum Melting Furnace manufactured and supplied from?

A: The furnace is manufactured, supplied, and exported from India using high-quality standards and engineering expertise, delivering solutions regionally and internationally.Q: What is the process involved in melting metals with this furnace?

A: Metals are loaded into the furnace and heated via induction coils. Once the desired temperature is reached, a vacuum is maintained to prevent contamination, allowing safe and clean melting and casting.Q: What are the benefits of using a vacuum induction furnace for industrial melting?

A: Key benefits include improved material purity, efficient melting cycles, reduced gas absorption, and customizable melting conditions for high-quality end products.Q: What kind of warranty and after-sales support can customers expect?

A: Customers receive a 1-year warranty with comprehensive after-sales support covering maintenance, technical guidance, and service to ensure reliable operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

MICROTECH INDUCTIONS (INDIA) PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese